Five-axis laser machine for processing any 3D part

Freedom to laser-cut three-dimensional parts

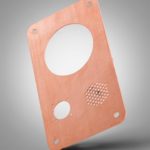

Bent tubes, hydroformed components, tubular assemblies or stamped parts. The LT-FREE five-axis laser cutting system is perfect for processing any three-dimensional part.

Freedom to laser-cut any metals, even 3D

Copper, aluminium, brass, mild steel, stainless steel, galvanised… The system is equipped with a fiber laser to process any type of metal with maximum efficiency and excellent cut quality every time.

Freedom to cut without repositioning the tube

In the Highflex version the entire tube is processed in a single cycle: the robot is used to reposition the part as required. This avoids the need for additional fixtures or operations.

Freedom from costly templates

The innovative part positioning system is quick and easy to configure and avoids the needs to make a dedicated template for each part. This is a significant saving of both time and costs.

Freedom to cut accurate parts, perfect even for laser welding

Laser cutting does not deform the part. The the cut is better and the results are more accurate and consistant. This is ideal for robotic welding. Laser is suitable for all thicknesses including thin walled tubes which are easily deformed during traditional operations.

Do what you do every day, in the best possible way

Cutting, piercing, punching, milling, deburring: these operations are traditionally performed in sequence one after the other. The laser does them all together in a single automated operation.

Obtaining the finished part without creating ‘work in process invnetory’ is a huge advantage.

Production is simplified, material handling costs are cut and the floor space needed for storage is eliminated.

Top flexibility and productivity

The extreme freedom of movement of the laser head and the use of automatic loading and unloading tables guarantees maximum system flexibility.

The independent double robot work station configuration allows loading and unloading in the background also while the laser continuously cuts.

A configuration for every need, up to 24 hours a day

Customize for your 24 hours a day production requirements utilizing automated loading and unloading.

HIGH FLEX version

Flexible configuration for processing bent or hydroformed tubes, flat or stamped sheets or welded assemblies. Uses dual part holding robots and double part loading tables for high throughput. Scrap is collcted separately from the parts.

MID FLEX version

For processing bent or hydroformed tubes and assemblies. There are two shuttle tables which automatically shift in and out of the laser work zone making it possible to load/unload and laser process parts at the same time. Processing alternates between the two tables so that production can run uninterrupted.

PIECE VALUE version

Piece Value configuration for processing large-size assemblies in large batch production. Piece Value has a dual station rotary work table which turns to enable loading and unloading while the laser is cutting.

ENTRY LEVEL version

For processing bent or hydroformed tubes and assemblies or flat sheet. The system offers two fixed worktables on which the work holding fixtures or tooling are mounted. Multiple parts can be fixtured for batch processing. Manual part loading and unloading take place after the laser cutting cycle has been completed.

Convenient and simple to use

Using LT-FREE is convenient and simple: operation can be continuously monitored via several internal cameras. Simply select your material type and thickness to automatically calculate all the cutting parameters and the optimal laser focus position.

Easy to use

The BLM GROUP software can be used to create part complex programs via easy to use 3D graphical simulations of the entire cell. Monitors for collisions and determinte the feasibility of the parts to be made.

Import a 3D models developed with another CAD systems (supported extensions: .iges and .step)

Select a specific part to be cut from the assembly drawing

Define the cut path and cutting sequence within the 3D environment

Simulate the cut path and edit in the 3D environment. No need to waste costly machine time making corrections to the cut path

Define of cutting positions for the part handling robot

Check for collisions and automatically or manually create the cut path

Programs are generated to manage the complete cell (cutting head and robot movements) using a dedicated post-processor

Infinite applications

Automotive

Industrial vehicles

Aerospace

Motorcycles

All-In-One: bending and laser cutting made for each other

Bending and laser cutting turns the tube into a finished product. But the use of two separate technologies can cause difficulties. BLM GROUP machines are designed to seamlessly interface the two technologies solving all of the possible upstream problems. All automatically.